How Material-Moving Equipment Can Cut Warehouse Downtime

- Multi-Mover

- Jul 23, 2025

- 5 min read

Updated: Oct 14, 2025

In a busy warehouse environment, even a few minutes of unexpected downtime can lead to delayed shipments, disrupted workflows, and increased operational costs. From missed delivery windows to reduced productivity, the knock-on effects can be significant. Luckily, powered movers, such as electric tugs, have transformed how warehouses operate.

In this guide from our experts at Multi-Mover UK, you can discover how powered movers can make material-moving operations more efficient and streamlined.

The Cost of Downtime in Warehousing

Downtime refers to periods when equipment is non-functional, leading to a pause in the normal workflow. As a result of the unplanned break in operations, downtime can seriously impact productivity, order fulfilment, and customer satisfaction. For businesses to succeed, it’s important to avoid unplanned downtime as much as possible. Here at Multi-Mover UK, our material-handling equipment is aimed at reducing downtime and ensuring operational efficiency.

How Material-Moving Equipment Can Minimise Downtime

In fast-paced industrial and construction environments, every minute of downtime can impact productivity and profitability. Fortunately, material-moving equipment can play a vital role in keeping operations moving along. In this section, discover three ways professional material-moving equipment can minimise downtime in your warehouse.

Speeds Up Handling Processes

Reducing the time spent moving materials manually can significantly contribute to a reduction in downtime. Material-moving equipment can reduce the total time spent walking, lifting and transferring items, ensuring your employees’ available time is used effectively in your warehouse.

Reduces the Likelihood of Lifting Injuries

Manual lifting and carrying can be key causes of injury in warehouses. A bad injury can leave employees incapable of completing their tasks, which in turn results in warehouse downtime. Luckily, material-handling solutions can help. These tools can minimise the physical strain on workers, reducing the likelihood of injury. Fewer injuries can also result in fewer employee sick days, helping to contribute to the overall productivity of the warehouse throughout the year.

Prevents Damage

Expertly designed material-moving equipment is equipped to move goods and materials safely, preventing damage from happening in transit. Carrying goods by hand means stock can often get knocked into nearby surfaces or dropped, damaging the product and potentially rendering it unusable. In contrast, material-moving equipment is designed to provide steady and smooth movement, reducing the chances of materials being damaged.

Comparing Material-Moving Equipment Types

In this section, you can discover everything you need to know about some key types of material-moving equipment. This information should help you determine which solution is most suitable for your warehouse and can effectively address downtime.

Automated Guided Vehicles (AGVs)

Automated Guided Vehicles, more commonly known as AGVs, are autonomous vehicles that transport goods within a warehouse. Unlike humans, these tools can operate continuously without fatigue. Their automated nature can also help to minimise mistakes caused by human error.

Powered Movers

Battery-operated, powered movers are handy, compact tools that can assist in moving heavy loads manually. These solutions are particularly advantageous, offering increased load capacity handling, manoeuvrability in tight spaces, and a reduction in operator fatigue and injury risk.

At Multi-Mover UK, we offer quality electric movers that allow users to move goods in both indoor and outdoor environments. These make the perfect addition to warehousing facilities, easily getting around and moving stock of various weights. Our Robik Electric Movers, while relatively compact, are still more than capable of providing exceptional lifting force.

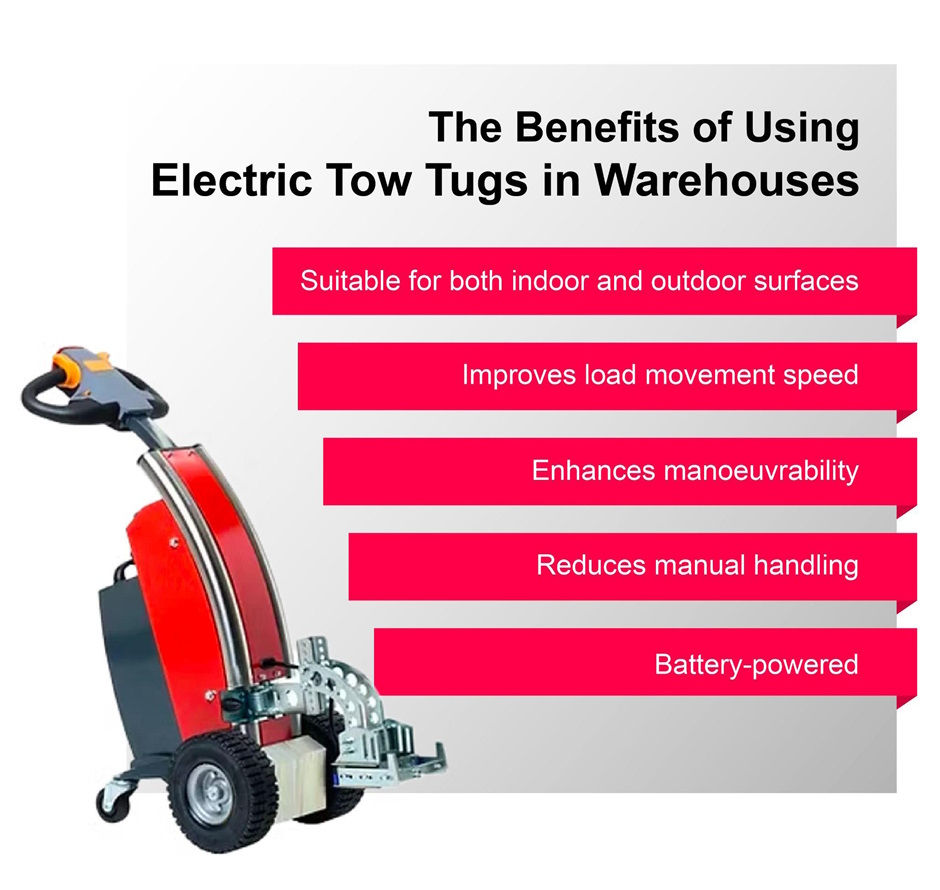

Electric Tugs

Designed to pull along carts, trollies, and trailers on smooth surfaces, electric tow tugs are wheeled systems that can work on both hard and soft surfaces. These solutions are chosen as they can improve load movement efficiency, offer precise control in a range of environments, and reduce the need for larger, more expensive equipment.

Here at Multi-Mover UK, our range of electric tow tugs includes products of various sizes and capacities, allowing you to easily find the right option for your workplace. The Multi-Mover S15 is great for loads up to 1,500kg, for example, while the Multi-Mover XXL 10T is perfect for both pushing and pulling up to 10,000 kg.

Heavy Equipment Movers

Warehouses can often stock heavy items that are especially challenging to move and manoeuvre. Luckily, there is an easy solution in heavy-equipment movers. These specialist tools are robust machines, designed to transport large and heavy items. They can handle substantial loads while still ensuring the relocation of sensitive equipment goes smoothly.

Tailoring Solutions to Specific Warehouse Needs

No two warehouses are the same, and neither are their equipment requirements. Selecting the right material-handling solution will start with understanding the unique demands of your space, products and processes. By carefully evaluating factors such as warehouse layout, you can make informed choices that enhance efficiency, reduce strain on staff, and keep operations running smoothly.

Assessing Warehouse Layout

Start by analysing the physical dimensions and flow of your warehouse. For tight spaces, compact and highly manoeuvrable electric tugs may be more suitable than larger vehicles. Understanding how goods move through your space allows you to choose equipment that complements rather than complicates your operations.

Understanding Load Types

Different products require different handling methods. If your warehouse regularly moves large pallets or heavy loads, you'll need robust equipment designed for weight capacity and stability. On the other hand, if you’re handling delicate or irregularly shaped items, you may need equipment that allows for more precise control and careful movement.

Evaluating Workloads

High-volume warehouses with rapid turnover rates demand equipment that can keep up with constant movement. This might mean investing in multiple machines to prevent downtime. Think about how often your team needs to move goods, how many loads are handled per shift, and whether activity levels change seasonally.

Best Practices for Maximising Equipment Efficiency

To get the most out of your investment in material-handling equipment, there are a few extra steps you can take in your warehouse. Below, find key tips from our experts at Multi-Mover UK.

Regular Maintenance

One of the best things you can do to ensure your equipment is working well and lasts a long time is to organise regular maintenance. Scheduled servicing carried out by an expert team can help ensure your moving equipment is ready for use, as these professionals will be able to identify any potential problems and existing issues.

Operator Training

Even the most advanced material-handling equipment can fall short if it’s not used correctly. Proper training ensures that all warehouse staff understand how to operate each machine safely and efficiently. This reduces the risk of accidents, which can lead to both injuries and equipment damage.

Skilled operators are also more likely to handle goods with care, preventing product loss through mishandling. Well-trained staff can complete tasks more quickly and with greater accuracy, contributing to an overall increase in workflow efficiency.

Warehouse Layout Optimisation

The layout of your facility has a direct impact on how efficiently material-handling equipment can be used. Creating clear pathways for movement, minimising sharp turns or narrow aisles, and designating proper loading and unloading zones can help operators move through the space with ease. This reduces the risk of collisions and delays and allows you to get full value from your investment in moving technology.

Invest in Your Warehouse Operations

Powered material-moving equipment provides a practical, proven way to streamline operations, protect your team from unnecessary strain, and keep goods flowing efficiently through your site. From improving safety and reducing manual handling to increasing speed and accuracy, the right tools can transform your warehouse into a more productive and profitable environment.

At Multi-Mover UK, we understand that every warehouse is different. That’s why we offer a wide range of high-quality material-handling machines designed to meet a variety of needs. Our friendly team is on hand to help you determine the best option for your workspace, whether you’re looking for an electric tow tug or a Robik Electric Mover.

Ready to take the next step? Visit our website to learn more about us and the services we offer, or contact our team today for expert advice and tailored recommendations.

Comments